ChemiREAC

- Thin Film

- Fast Heating

- Versatile

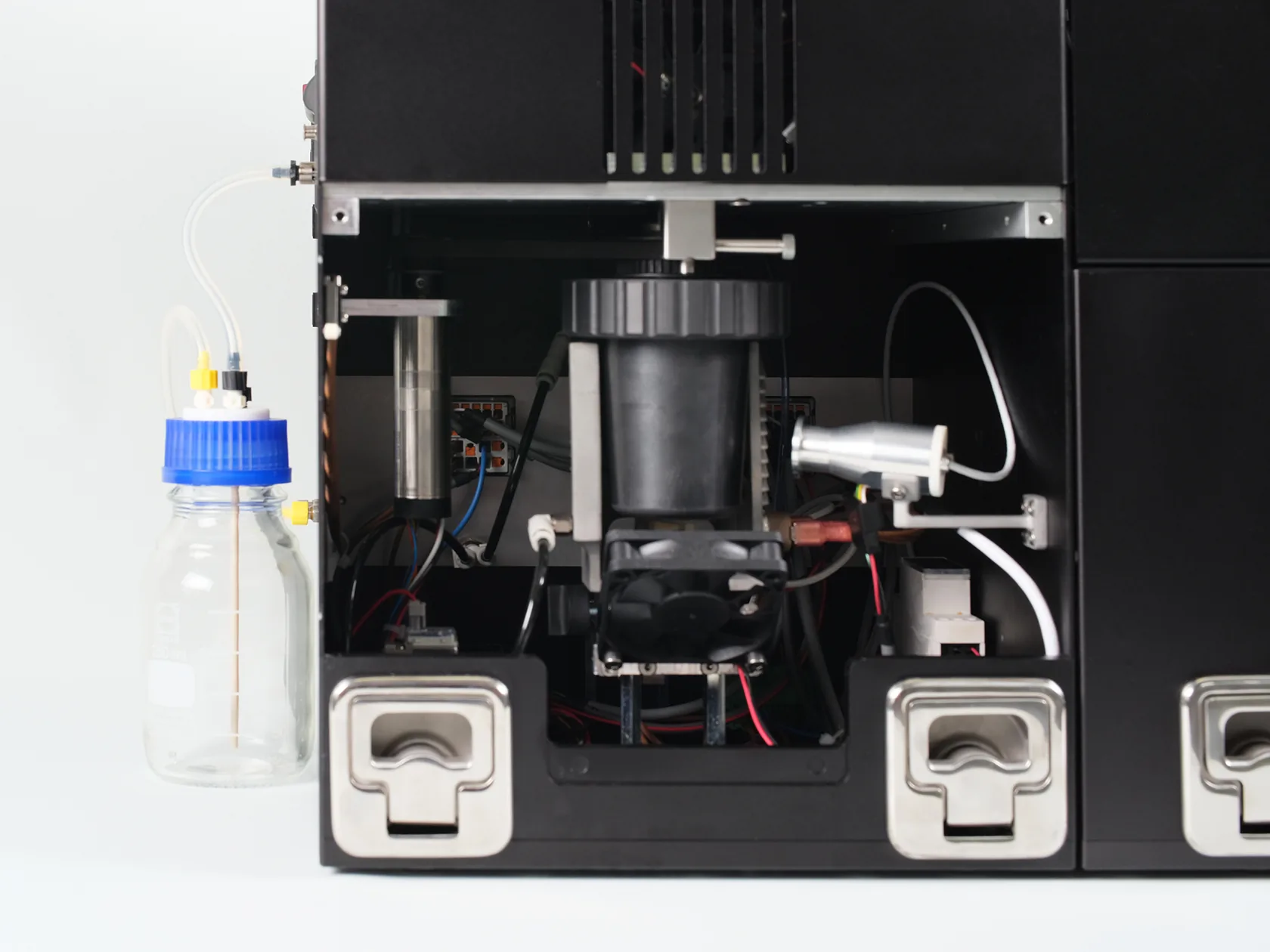

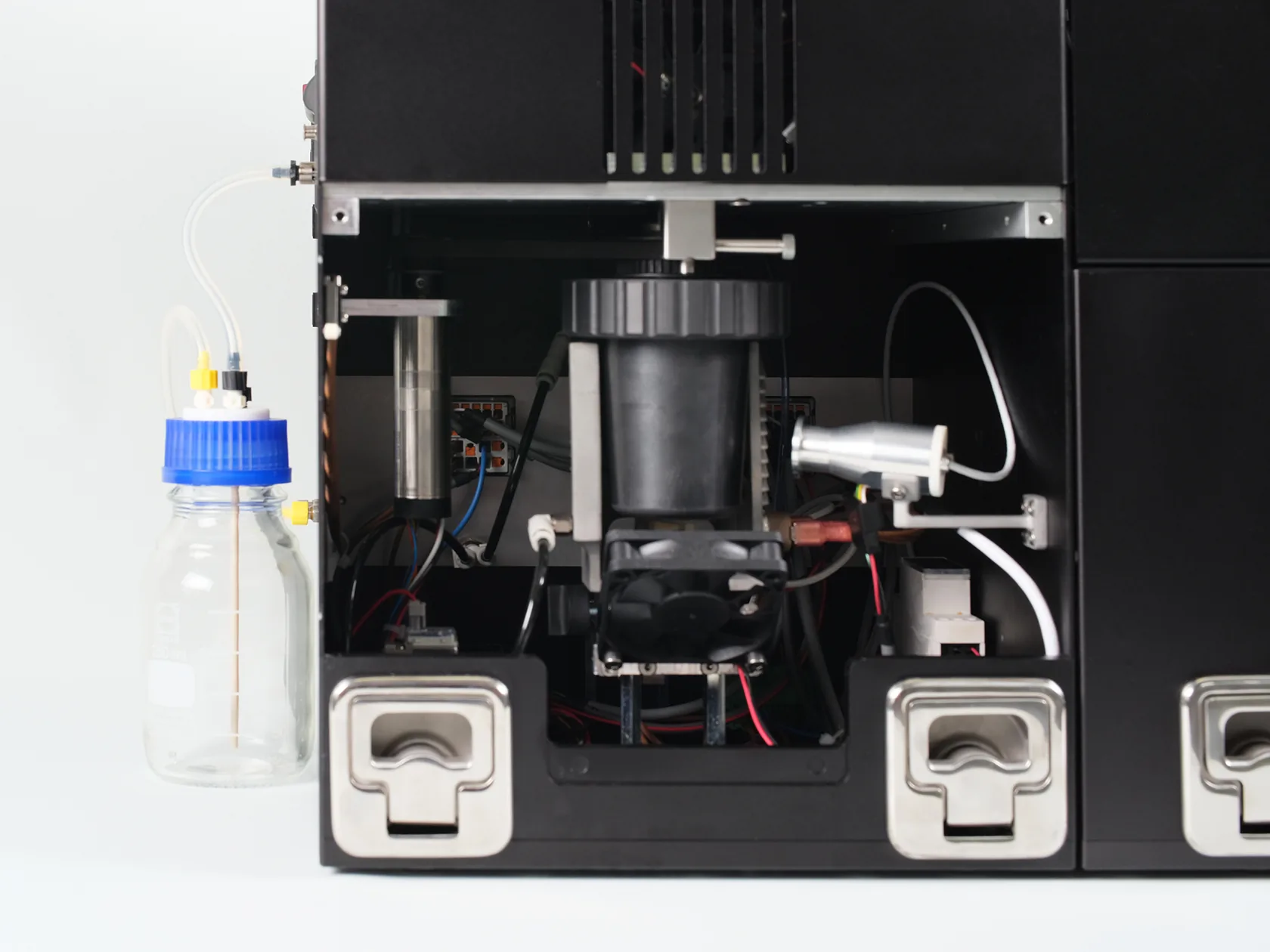

New Revolutionary and Automated Thin Film Reactor for a Wide Range of Chemistries

Unleash the power of thin-film chemistry with the ChemiREAC module. Its innovative design supercharges mass and energy transfer, dramatically reducing solvent use while boosting yields, speeding up kinetics, and delivering pinpoint reaction selectivity. Get ready for smarter, more efficient chemical transformations.

Key Features

- Elevate your chemistry. Our thin-film reaction technology (0.4 mm-3 mm) delivers exceptional performance. Precision rotation, including dynamic mixing waves, promotes higher yields, better selectivity, and dramatically reduced reaction times versus standard lab glassware.

High Versatility

Thanks to its broad chemical compatibility, ChemiREAC equipment allows you to explore a wide range of chemical reactions in catalysis Suzuki, biocatalysis, organometallics, heterocyclization, oxidation and even complex "one pot" and multi-step synthesis.Fast & Efficient Heating System

Optimize your reactions with intelligent heating. Our system's efficient radiative heating and IR monitoring offer responsive temperature control. Low thermal inertia means no overshoots and instant cooling for ultimate process precision.Pressure & Vacuum Control

Gain total control over your reactions. Our closed, pressure-monitored vessel enables chemistry beyond the boiling point and effortless removal of all solvents, including high-boiling point solvent such as DMF.High Level of Safety

Push the boundaries of your chemistry with confidence. Our module is engineered for extreme durability, withstanding high temperatures and pressures up to 6 bar. It features proactive exotherm detection and intelligent countermeasures to prevent runaway reactions. For ultimate protection, a failsafe automatic stop engages if any reaction parameter moves outside safe operating thresholds.

Future Innovation

Photochemical Reactor

To take advantage of the thin film and facilitate and to unlock new possibilities in synthesis.

Upscaling

ChemiREAC's early development proved its remarkable ability to seamlessly scale thin-film reactions, achieving efficient upscaling from micro-liter volumes (100 µL) all the way to 250 mL. Building on this success, Synlock is working on the next ChemiREAC1000 (for 100 mL-1000 mL reaction media), set to supercharge your production capacity and drive larger-scale chemical transformations.

Coating

Coating of inner wall of the reaction vessel with various solid supported reagent and catalyst will be soon available.

Specifications

| Reaction Vessel Volume |

|

|---|---|

| Reaction Media Volume Range |

|

| Material | Reaction vessel: silicium carbide SSiC Inert Wetted part: PEEK, 316L Stainless Steel Shell: Anodized Aluminium |

| Rotational Speed | 100 rpm to 1500 rpm |

| Temperature | 25°C to 180°C |

| Heating Rate | 1.5°C/s |

| Accuracy | ±1°C |

| Pressure Range (relative) | 100 mbar to 6 bar |

| Vacuum | Down to 100 mbar |

| Overpressure Safestop | Over 6 bar |

| Cooling | Pneumatic cooling |

| Dimensions | 29.9 × 29.5 × 39.2 cm (L x l x h) |

| Weight | 10.9 kg |

| Stirring mode | mechanical |